Below are links to pages providing tips and answers to many questions asked by septic system owners.

How often does my septic tank need to be pumped?

Septic Tank Pumping Guide

Having surveyed and collected septic system design and testing information from many U.S. states and Canadian Provinces, I think that information provided by the Penn State College of Agriculture – Cooperative Extension is clear and representative of expert thinking on this topic. For clarity and content I’ve made minor edits to the original material.

Understanding the Septic System

The most common domestic wastewater treatment system used in rural areas is the septic tank-soil absorption system. The septic tank removes settleable and floatable solids from the waste water. The soil absorption field then filters and treats the clarified septic tank effluent and distributes it through the soil. Removing the solids from the wastewater protects the soil absorption system from clogging and failure. In addition to removing solids, the septic tank also promotes biological digestion of a portion of the solids and stores the remaining undigested portion.

The first stage of the treatment system, the septic tank, removes solids by holding wastewater in the tank. This allows the heavier solids to settle as sludge and the lighter particles to form scum at the top. To accomplish this, wastewater should be held in the tank for at least 24 hours. Up to 50 percent of the solids retained in the tank decompose; the remainder accumulate in the tank. Biological and chemical additives are not needed to aid or accelerate decomposition.

When should septic tanks (onsite sewage disposal system holding tanks) be pumped?

As the system is used, sludge continues to accumulate in the bottom of the septic tank. Properly designed tanks have enough space for up to three years safe accumulation of sludge. When the sludge level increases beyond this point, sewage has less time to settle before leaving the tank and more solids escape into the absorption area. If too much sludge accumulates, no settling occurs before the sewage flows to the soil absorption field. Infiltration of sludge into the soil absorption field can cause system failure. To prevent this, the tank must be pumped periodically. The material pumped is known as septage.

frequency of pumping depends on several factors:

- capacity of the septic tank

- volume of wastewater (related to size of household)

- amount of solids in wastewater (e.g. garbage disposals produce more solids)

Table I lists estimated pumping frequency according to septic tank capacity and household size. The frequencies were calculated to provide a minimum of 24 hours of wastewater retention assuming 50 percent digestion of the retained solids.

| Tank Size (gal) |

Household size (number of people) |

|||||||||

|

1 |

2 |

3 |

4 |

5 |

6 |

7 |

8 |

9 |

10 |

|

|

Years between pumping |

||||||||||

|

500 |

5.8 |

2.6 |

1.5 |

1.0 |

0.7 |

0.4 |

0.3 |

0.2 |

0.1 |

– |

|

750 |

9.1 |

4.2 |

2.6 |

1.8 |

1.3 |

1.0 |

0.7 |

0.6 |

0.4 |

0.3 |

|

900 |

11.0 |

5.2 |

3.3 |

2.3 |

1.7 |

1.3 |

1.0 |

0.8 |

0.7 |

0.5 |

|

1000 |

12.4 |

5.9 |

3.7 |

2.6 |

2.0 |

1.5 |

1.2 |

1.0 |

0.8 |

0.7 |

|

1250 |

15.6 |

7.5 |

4.8 |

3.4 |

2.6 |

2.0 |

1.7 |

1.4 |

1.2 |

1.0 |

|

1500 |

18.9 |

9.1 |

5.9 |

4.2 |

3.3 |

2.6 |

2.1 |

1.8 |

1.5 |

1.3 |

|

1750 |

22.1 |

10.7 |

6.9 |

5.0 |

3.9 |

3.1 |

2.6 |

2.2 |

1.9 |

1.6 |

|

2000 |

25.4 |

12.4 |

8.0 |

5.9 |

4.5 |

3.7 |

3.1 |

2.6 |

2.2 |

2.0 |

|

2250 |

28.6 |

14.0 |

9.1 |

6.7 |

5.2 |

4.2 |

3.5 |

3.0 |

2.6 |

2.3 |

|

2500 |

30.9 |

15.6 |

10.2 |

7.5 |

5.9 |

4.8 |

4.0 |

3.5 |

3.0 |

2.6 |

Note: More frequent pumping is needed if a garbage disposal is used. Generally the indicated frequency will vary with the volume of solids (+20% for high volume, -20% for low volume). Under current Pennsylvania law a 900 gallon septic tank is the minimum size that must be used for a home with three bedrooms or less. If six people reside in a three-bedroom house, the tank should be pumped every 1.3 years. If the same system serves a family of two, the tank would be ready for pumping every 5.2 years. Systems installed before the current rules and regulations were implemented may need to be pumped more often, perhaps every year or less.

As indicated in the footnote to Table 1, garbage disposers will increase the frequency of pumping. For example, if this same three bedroom house with six residents had a garbage disposal and was generally producing a higher volume of wastewater, the pumping frequency would be calculated as follows:V

1.3 years – [(0.2) x 1.3 years] = 1.0 year

If you have just moved into a home, you may not know the size of the tank. In this case, you should have the tank pumped and inspected. The company pumping the tank will tell you its size, age, and condition.

What causes failures?

Septic tanks will not fail immediately if they are not pumped. However, an un-maintained septic tank is no longer protecting the soil absorption field from solids. Continued neglect may result in system failure and even replacement of the soil absorption field. In some cases, site limitations may make replacement of the absorption field impossible. If system replacement is the only option, contact your local Sewage Enforcement Officer (SEO) or municipal sanitarian or health department since a permit for the new system will be required.

More explanation: In order for a tank to function properly, adequate liquid volume must be maintained to allow for sufficient “settling time” which permits solids to either settle out as sludge or join the floating-scum layer at the top of the tank. Baffles in the tank prevent the floating scum from leaving the tank, an event which would lead to rapid failure of the absorption system. When pumping is too infrequent, even if the tank is not totally clogged with solids, the reduced liquid volume in the tank cuts settlement time and forces small floating solids out to the absorption system, shortening its life.

Cleaning Septic Tanks

Septic tank pump and haul contractors can clean your tank. It is a good idea to supervise cleaning to assure that it is done properly. To extract all the material from the tank, the scum layer must be broken up and the sludge layer mixed with the liquid portion of the tank. This is usually done by alternately pumping liquid from the tank and re-injecting it into the bottom of the tank. The septic tank should be pumped through the large central manhole, not the baffle inspection ports. Pumping a tank through the baffle inspection ports can damage the baffles, resulting in a destroyed leach field.

The use of additives in septic tanks to reduce the sludge volume or substitute for pumping is not recommended. In fact, relying on additives rather than conventional tank pumping may result in failure of the septic system. Septic Addatives are illegal in many jurisdictions.

Before closing the tank, check the condition of the baffles. If they are missing or deteriorated, replace them with appropriate sanitary tee baffles. It should never be necessary to enter a septic tank. Any work to replace the baffles or repair the tank should be done from the outside. Decomposing wastes in the septic tank produce toxic gases which can kill a human in a matter of minutes. When working on a tank be sure the area is well ventilated and that someone is standing nearby. Never go into a septic tank to retrieve someone who has fallen in and was overcome by toxic gases without a self-contained breathing apparatus (SCBA). if a SCBA is not available, call for emergency services and put a fan at the top of the tank to blow in fresh air.

To facilitate future cleaning and inspection, install risers from the central manhole and inspection ports to the surface before burying the tank Also mark the location of the tank, so it can be easily identified.

Summary

The septic tank is only one part of an on-site wastewater system. It is designed to remove solids prior to the effluent entering the soil absorption field, provide for the digestion of a portion of those solids, and store the remaining solids. Biological and chemical additives are not needed to aid or accelerate decomposition. Garbage grinders impose an additional solids load on the system. Solids must be removed periodically to prevent them from entering the soil absorption field. For a properly designed septic system, the tank should be inspected and pumped every 1 to 5 years.

I need to know what size septic tank I need to put in.

Septic Tank Capacity vs. Usage

Typical residential septic tank size required for given average daily sewage flow in gallons. Links to related septic system testing and design information.

|

Average sewage flow gallons per day

|

Minimum Gallons Effective Capacity(1)

|

|

0-500

|

900

|

|

601-700

|

1200

|

|

801-900

|

1500

|

|

1001-1240

|

1900

|

|

2001-2500

|

3200

|

|

4501-5000

|

5800

|

(1) Source: Florida ASHI Seminar, Kissimmee, October 1993, included sheet from Environmental Health Services, March 17, 1992. Some intermediate table entries were eliminated but can be recalculated by interpolation. In most U.S. jursidictions we surveyed, the minimum permitted tank size for new septic installations is 1000 gallons. Special site considerations may require design by a septic-engineer before local health departments can approve nn installation.

How much water usage does my household have as it pertains to my septic tank?

Home & Outdoor Living Water Requirements

The table below shows the typical residential water usage for people, appliances, and activities.

Home and Outdoor Living Water Requirements Source: USDA “Water Systems Handbook.” (Thanks to Keith Oberg, Professional Home Inspection Service, Binghamton, NY, for providing this information.)

Table 1. Home and Outdoor Living Water Requirements

|

Use

|

Flow rate (gpm)

|

Total use (US Gallons

|

|

Adult or child

|

–

|

50-100/day

|

|

Baby

|

–

|

100/day

|

|

Automatic washer

|

5

|

30-50/load

|

|

Dishwasher

|

2

|

7-15/load

|

|

Garbage Disposer

|

3

|

4-6/day

|

|

Kitchen Sink (a)

|

3

|

2-4/use

|

|

Shower or tub

|

5

|

25-60/use

|

|

Toilet Flush

|

3

|

4-7/use

|

|

Bathroom Lavatory Sink

|

2

|

1-2/use

|

|

Water softener regeneration

|

5

|

50/100/cycle

|

|

Backwash Filters

|

10

|

100-200/backwashing

|

|

Outstide hose faucet

|

5

|

?

|

(a) water flow restricting valves and shower heads can reduce flow and water use by up to 50%.

Reverse Osmosis Systems – impact on septic systems and water use:

What about water volume from reverse osmosis water treatment systems? These can vary by manufacturer with a range of 3:1 to 10:1 of waste to product effeciency. “Typically” for every gallon produced with a topo of the line system, 3 to 5 gallons goes into the septic tank. Less effecient systems (regardless of shutoffs) can dump up to 10 gallons to waste for every gallon that goes into the storage tank. Don’t despair…the membranse of ten years ago dumped up to twenty five gallons per gallon of product.

For concurrence: ask the manufacturer for their effeciency, platform statement, and per cent recovery. An ecellent resource for membrane information is the National Sanitation Foundation. I am not confient about the generilized information you obtain via EPA publications, Small Flows, etc. If you posture your inquiries with the reputable manufacturers, you should be able to get reliable flow information.

Do I need to add chemicals, nutrients, cleaners, or decloggers to my septic tank?

Should you add chemicals, nutrients, cleaners, decloggers to septic systems?

No! Why not? What causes failures?

Septic System Additives and Chemicals

Chemicals and other additives promoted to keep a septic system “healthy” or “free-flowing” or “nourished” are generally not required nor recommended by any known expert sources. The following references support this statement:

Penn State College of Agriculture – Cooperative Extension:

Agricultural Fact Sheet #SW-161 “Septic Tank Pumping,” by Paul D. Robillard and Kelli S. Martin – last line of second paragraph “Biological and chemical additives are not needed to aid or acclerate decomposition.”

Agricultural Fact Sheet #SW-161 “Preventing Septic System Failures,” by Paul D. Robillard and Kelli S. Martin – page 2, Maintenance Failures, paragraph two, “Chemical or biological additives are not a substitte for pumping.”

“Soil Science Facts, Septic Tank Systems,” Michael T. Hoover, Dept. of Soil Science, North Carolina State University, Raleigh, SS 86-4, “Are Septic-TankCleaners Necessary?” “No. These products include biologically based materials (bacteria, enzymes, and yeast), inorganic chemicals (acids and bases), or organic chemicals (including solvents). They do not reduce the need for regular pumping of the septic tank. Some of these products contain organic chemicals and may even damage the drainfield or contaminate the groundwater and nearby wells.”

Florida ASHI Seminar, Kissimmee FL, 10/10/93, “Septic Tank News & Views,” cites Florida building code 10D-6.050 Maintenance, paragraph (4) “Organic chemical solvents shall not be advertised, sold, or used in the state fdor the purpose of degreasing or declogging onsite sewage disposal systems. (4)(a) All organic chemical solvents known to have been used as decloggers or degreasers of onsite sewage disposal systems or those which have a liklihood of being used in such a manner shall be labeled on the front of each product container with the following language: ‘Florida Statute 381.0065 (13) prohibits the advertisement, sale or use of organic chemical solvents for the purpose of degreasing or declogging onsite sewage systems in the state.’ … ” and (4)(b) continues, “Persons who use organic chemical solvents for degreasing or declogging onsite sewage disposal systems shall be subject to revocation of their septage disposal service permits and shall be subject to other applicable penalties as described in Chapter 381, or 489 Part III,F.S.” These law changes were effective in Florida march 17, 1992.

“Septic Tank Maintenance,” K. Mancl and J.A. Moore, Oregon State University Extension Service, Extension Circular 1343/January 1990. “Biological and chemical additives are not needed to aid or accelerate settling or decomposition.”

The view that chemical and other additives are not necessary, and in some jurisdictions are illegal, was held by information we collected from every U.S. state as well as Canadian sources.

Our Canadian sources have offered the most detailed explanation of these issues. (Thanks to Alan Carson, Carson Dunlop, Associates, Toronto, Ontario, for providing this information.) See “Manual of Policy, Procedures, and Guidelines for Onsite Sewage Systems,” Referring to Ontario Regulation 374/81 under part VII of the Environmental Protectin Act, ISBN 0-7743-7303-2.

Ontario, Canada, Ministry of the Environment, “9.4.1 Class 4 Sewage Systems, Construction, Operation, and Maintenance,” May 1982.

Paragraph 3(f)(i) Chemicals: “The function of a septic tank is not improved by the addition of disinfectants or other chemicals. In general, the additary products which are claimed to “clean” septic tanks contain sodium hydroxide or potassium hydroxide as the active agent. Such compounds may result in sludge bulking and a large increase in alkalinity, and may interfere with digestion. The resulting effluent may severely damage the soil structure and cause accelerated clogging, even though some temporary relief may be experienced immediately after application of the product.”

3(f)(ii) Frequently however, the harmful effects of ordinary household chemicals are overemphasized. Small amounts of chlorine bleaches, added ahead of the tank, may be used for odour control and will have no adverse effects. Small quantities of lye or caustics normally used in the home, added to plumbing fixtures, are not objectionable as far as operation of the tank is concerned. If the septic tanks are as large as required by regulation, dilution of lye or caustics in the tank will be enough to overcome any harmful effects that might otherwise occur.

3(f)(iii) Some 1200 products, many containing enzymes, have been placed on the market for use in septic tanks, and extravagant claims have been made for some of them. As far as is known, none has been proved advantageous in properlycontrolled tests.

3(f)(iv) Soaps, detergtents, bleaches, drain cleaners, or other material as normally used in the household will have no appreciable adverse effect on the system. However, as both the soil and essential organisms might be susceptible to large doses of chemicals and other disinfectants, moderation should be the rule. Advice of responsible officials should be sought before chemicals arising from a hobby or home industry are discharged into the system.

3(f)(v) Adsorption trenches or filters can become clogged due to the plugging of the voids in the stone layer with soil particles, or due to the build-up at the soil/sewage interface of a black, slimy deposit composed of organic wastes, bacteria, inorganic precipitates and other debris, occurring due to the age of a system or to its overloading with solids. A combination of these causes may also occur. Where a slimy deposit is causing or contributing to clogging, rejuvenation of the soil/sewage interface may be accomplished by removing any stagnant water from the system and injecting a strong solution of hydrogen peroxide. This form of chemical restoration was developed and patented (1977) by the Wisconsin Alumni Research Foundation (WARF) and the process named POROX. Applications using hydrogen peroxide to restore leaching beds must be licensed by WARF.

Because of the dangers of handling this strong oxidant, this treatment should be done by professinals. Confirmation that slimy deposits are clogging the field can be determined by measuring the liquid level in one or more absorption grenches and comparing it to the level of ground water in an augered hole located a few feet from the bed perimeter. Inspection of the trenches by exposing portions at two or more dispersed points in the leaching bed will indicate whether the clogging is general in all distribution lines and if the voids in the stone are filled or partly filled with soil. If the voids are filled POROX treatment would not have as lasting an effect. If judged suited to rejuvenation by POROX, it is important that the septic tank be pumped and that all static liquid is removed from the absorption trenches prior to the treatment.

What are Septic Systems?

Septic systems are considered to be on-site systems designed to safely dispose of biological sanitary waste. “Gray water”, such as laundry waste, is part of the waste system, but it may not result in what is referred to as “biological” waste. We will address “gray water” waste as it impacts the design of a septic system.

How do Septic Systems Work?

Basically a septic system provides a “holding Tank” where natural bacterial action decomposes human waste products into environmentally acceptable components – the major end-components being water, mixed with some other components that are not readily consumed by the bacterial action, gases, and undigested solids. The end products, except the undigested solids, are then discharged to the on-site environment.

What are the Components of a Private Septic System?

The things that are most obvious are the things seen every day – the sinks, toilets, and pipes in a normal house. What are not visible are the things that are underground; the things that are underground, and the ground itself, greatly impact how a septic system works.

The individual parts of the system are the septic tank, a distribution box, and a leach field. Bacterial action takes place in the septic tank where the end products are mainly water, gases, and undigested material, called sludge that sinks to the bottom of the tank and scum that floats to the top of the tank. The septic tank contains baffles that prevent any scum that floats to the surface and sludge that settles to the bottom from passing out of the tank. The gases that are generated vent to the atmosphere via the plumbing vent system. From the septic tank, the segregated and relatively clear liquid flows into a small distribution box where it is then metered out to several perforated pipes. These perforated pipes then deliver the liquid to a large soil surface area, called a leach field, or absorption field, for absorption. The soil also acts as a filter to remove any small amounts of solids that may be carried along with the liquid. The sludge in the bottom of the tank must be periodically pumped out and properly disposed of.

There are other kinds of systems for special situations, but the septic tank and leach field is the most widely used system in our area. The following discussion concentrates on this type of system.

Where are These Components Located?

The concrete, or sometimes steel, septic tank is buried in the ground, usually a minimum of 10 feet from the house. The top of the tank is usually about one foot below the soil surface so it can be periodically opened for inspection and pumping. If you do not know for sure where the tank is located, the first step is to locate where the house sewer pipe leaves the house. In a house with a basement, this is where the pipe passes through the wall. Locating the exit point may be more difficult for a house with no basement. If the pipe exit can be found, the tank normally begins about 10 feet from the house outside wall and in line with the house sewer pipe. If the soil is not frozen, you can usually find the tank by pushing a slender metal rod into the ground until it hits the buried tank. You can buy a metal rod about 1/8 inch in diameter for a few dollars at most hardware stores. Be careful when probing for the tank and avoid hammering the metal rod into the ground – you could break a sewer pipe.

The distribution box is much smaller than the septic tank and is usual found about 20 feet from the house. It too is usually only about one foot below the ground. Again, you can probe the soil carefully to locate the distribution box with a slender metal rod.

From the distribution box, several pipes direct liquid to a series of pipes in trenches called laterals. The pipes in the trenches have holes in them to allow the liquid to be evenly distributed within the trench. To keep the pipes from being blocked with soil and to provide a space for water to be stored while it is being absorbed by the soil, the pipes are laid in a bed of crushed stone. Above the stone is a soil filter (usually one or two layers of what is called untreated building paper). Above the soil filter is top soil in which grass is planted.

Equally important is WHERE THE COMPONENTS SHOULD NOT BE. If there are wells, either yours or a neighbor’s, the leach field must be a minimum of 100 feet from the location of the well. In some areas, the well is not allowed to be down-slope from the leach field. If there is a stream or pond, the leach field must also be a minimum of 100 feet from the mean high water mark. Normally, no part of the system should be within 10 feet of a property line. In some areas and in unusual conditions, minimum distances may be greater than those noted here. In addition, no part of the system should be under a porch or driveway and you should not drive heavy vehicles (including automobiles) over the system lest the system be damaged.

Care and Maintenance

Conventional septic systems are not entirely care free. The undigested solids (sludge) in the bottom of the septic tank should be pumped out every two to four years, depending on usage and tank size. If the sludge is not removed periodically, it will eventually carry over into the leach field and cause the field to fail.

A well designed system can handle a reasonable amount of normal household chemicals such as drain cleaners, laundry detergent and bleach; excessive usage can be detrimental. You should avoid putting in chemicals that are toxic to the bacteria, such as paint thinner, solvents, insecticides, etc. Cooking fats and grease should also be avoided. If a garbage disposal is used, more frequent tank pumping may be needed.

Depending on the size of the tank and your location, plan on a cost of about $200 each time the tank is pumped. When the tank is pumped, your service person should also check the tank baffles for possible damage; ask them to do this inspection before you contract with them. While the tank is open, the service technician can also run some water from a hose into the distribution box to get an indication that the leach field is also still functioning; ask if the company offers this service.

Why Septic Systems Fail

If the liquid effluent cannot soak into the soil surrounding the leach field, sewage may back up into the system and overflow into the house or puddle on the surface of the ground. There are several possible causes for this problem.

- Poor Soil Conditions; Faulty Design or Installation

A leaching system placed in unsuitable soil, a system that is too small for the house it serves, or an improperly constructed system may lead to early failure. - Soil Clogging

If sludge or scum is allowed to escape into the distribution box and from there into the leach field, the soil will quickly become clogged. If this happens, the liquid will no longer soak, or percolate, into the soil. This condition can be caused by broken baffles in the septic tank that allow sludge or scum to escape. Failure to have the tank pumped can also lead to a situation where the sludge and scum overwhelm the baffles. - High Water Table

During wet, or abnormally wet, seasons groundwater may rise into the leach field and force sewage upward to the ground surface. This condition may mean the system has to be re-installed at a higher level. It may also be possible to intercept the high groundwater with a series of drains around the system called “curtain drains”. - Roots

The roots of trees and bushes planted too close to the system can sometimes enter and block the pipes of the system. Removal of the plants and clearing the pipes of the roots is usually required. - Physical Damage

Trucks or heavy equipment passing over the system can damage pipes and joints to the point of rendering the system inoperable. You should be aware of the location of the system and direct traffic to avoid such damage.

How Long Should a Septic System Last?

You can expect a conventional septic system, such as that being described here, to last about 30 years. Some systems last much longer and some systems can fail earlier for reasons like those noted above. Other things can also affect the life of a septic system. For example, a system may have been providing satisfactory service for a previous owner for many years, only to fail shortly after you have bought the house. If the previous owners were a working couple with no children, the system was probably not heavily used; if yours is a family of six, the added load could push a marginal system over the edge and into failure.

What are the Signs of a Failing System?

Sewage backup into the home is one possible sign of a failing system. However, backup can also be simply the result of a blockage somewhere between the house and the septic tank (this is relatively easy to fix). Another possible sign of failure is a smell of sewage outside the house. If this smell is more noticeable after a lot of water has been put into the system – multiple showers or several loads of laundry (if the laundry waste discharges into the septic system), for example – this may be an indication that the leach field is failing. The smell may also be accompanied by a “spongy” feeling in some areas of the leach field, near the distribution box, or near the septic tank. The “spongy” feel may be caused by water and waste being pushed to or near ground level. If ponding water is also seen, this is called “breakthrough” and is an almost positive indication of failure of one or more parts of the system. This smell, however, can also originate at the plumbing vent. In either case, further investigation is warranted.

If you see such signs, a dye test may confirm your suspicions. For this test, a special strong dye is put in the system – usually by flushing it down the toilet. A significant amount of water is then washed into the system. If there is “breakthrough”, the dye will become visible on the ground surface. If the dye is seen on the surface, this would be a very strong indication that the system has failed. Your Home Inspector, a licensed professional engineer, or a septic system contractor can usually perform this test for you if it is needed.

If I Plan on Repairing, Installing, or Replacing A System, What should I expect?

There are two major factors involved in adding a new system or repairing or replacing an existing one. The first is the cost; the second is the inconvenience of possibly not being able to use the existing system while a replacement is being installed. For new construction, the second factor is not usually a major consideration.

Repair or replacement cost will obviously depend on what has to be repaired and/or replaced. If the repair does not involve the leach field, the cost may be high, but it will probably not be exorbitant. The least expensive repair will be associated with a broken pipe between the distribution box and the house. The cost for this type of repair is in the order of several hundred dollars. If only a septic tank needs to be replaced – and the leach field is still undamaged – the cost will be in the order of about $1500 to $2500. If a new leach field is needed, and there is room for such an installation, you should plan on spending an additional $2000 to $3000 for a typical home. If there is not sufficient room for a new leach field, the existing field, including the clogged soil, must be removed and a completely new system must be installed. Such an effort can easily exceed $10,000.

If my Family is Growing and I add a New Bedroom, What Should I Expect?

Septic systems are designed to dispose of household biological waste. The amount of waste to be handled depends on a number of factors. Among these are the number of people living in the house and their lifestyle. After many years of experience, a major guideline in determining the size and capability of a septic system has been correlated to the number of bedrooms in a house. The number of bedrooms typically determines the number of people generating waste and hence the amount of waste that must be handled. If your family is growing and a new bedroom is needed, then the load on the septic system is also increased. If the septic system capability does not keep up with the increased demand, system failure may occur.

So, how do you determine the septic system needs for your growing family? The following sections deal mainly with sizing a septic system so that it can adequately perform the desired function. Your design professional can handle the actual testing and number-crunching – but we have provided some standard guidelines developed by New York State to aid you in discussing your options with your contractor. You may not need all this information, but it could help in making your decisions.

How Big Should a Septic Tank Be?

Septic tanks are sized according to the amount of liquid waste they must process. This is done by counting the number of bedrooms. In New York State the minimum size tank that can be installed now is 1000 gallons for a 1, 2, or 3 bedroom house. For each bedroom after 3, add 250 gallons to the size of the tank. If a garbage grinder is in the kitchen sink, it counts as an additional bedroom.

How Big Should the Leach Field Be?

Determining the required size of a leach field is a bit more complicated. The first thing to consider is the nature of the soil in which the leach field is to be constructed. Because water has to be absorbed in the soil, we need to know how fast it can be absorbed. This is called the percolation rate and is expressed as the time it takes for water in a test hole to decrease in level by one inch (minutes/inch). We must also know the type of soil and whether seasonal changes in the natural level of groundwater will interfere with the satisfactory operation of the system. Seasonal groundwater must be more than four feet from the bottom of the leach field trenches. Judgments regarding the soil conditions and percolation rates are best left to a professional. If the soil percolates very fast (less than one minute per inch) or very slow (greater than 60 minutes per inch) it will not be possible to install a standard leach field in the existing soil.

We must now determine the amount of water that has to be absorbed each day. As with the septic tank sizing, there are also “rules of thumb” that can be used to find out how much water must be absorbed each day for each bedroom in the house (expressed as gallons per day per bedroom). For older houses (built before 1979) we must allow 150 gallons per day (gpd) per bedroom. For houses where the toilets are limited to no more than 3.5 gallons per flush and the faucets and showerheads are limited to 3 gallons per minute or less, we must allow 130 gpd per bedroom. For houses with water-saving toilets that use only one gallon per flush we allow 90 gpd per bedroom. The required flow rate is found by multiplying the appropriate flow by the number of bedrooms (in this case, we do not have to count a garbage disposal as a bedroom).

Knowing the rate at which water can be absorbed by the soil (the percolation rate) and the flow rate (in gallons per day), we can use the following table to calculate how many square feet of absorption field is needed.

|

Absorption Percolation

(minutes per inch) |

Application Rates

(Gallons per Day per Square Foot) |

|

1 – 5

|

1.2

|

|

6 – 7

|

1.0

|

|

8 – 10

|

0.9

|

|

11 – 15

|

0.8

|

|

16 – 20

|

0.7

|

|

21 – 30

|

0.6

|

|

31 – 45

|

0.5

|

|

46 – 60

|

0.45

|

Soil with a percolation rate less than 1 minute per inch or more than 60 minutes per inch is unsuitable for a conventional system.

Required Area (square feet) = Flow Rate (gallons per day) / Application Rate (gallons per day per square foot)

Now that we know the number of square feet of absorption field that is needed, we can divide by the width of each trench to see how many feet of trench is required. The normal trench width

Assume you are buying a 3-bedroom house that was built in 1971. The leach field has failed and a new one must be installed. You have had a percolation test performed and the design professional has determined that the soil is suitable, the groundwater conditions are acceptable, and the percolation rate is 32 minutes per inch. How big an absorption field will be needed?

Since the house was built before 1979, the flow rate is 3 bedrooms times 150 gallons per day per bedroom, or 450 gallons per day. From the table above, the application rate is 0.5 gallons per day per square foot for a percolation rate of 32 minutes per inch. The required trench area is then 450 gallons per day divided by 0.5 gallons per day per square foot. You will need 900 square feet of absorption area. If the absorption trenches are 2 feet wide, you will need a total of 450 feet of absorption trench. Most health codes limit the length of any one trench (called a lateral) to no more than 60 feet, the minimum number of laterals is 450 feet divided by 60 feet per lateral, or 7.5 laterals. Where property conditions permit, it is best to keep the laterals the same length, so your design professional may specify 8 laterals, each 60 feet long. But what if there is only room on the property for laterals that are 45 feet long. In this case, you would need 10 laterals, or trenches. In addition to the area needed for the leach field, you should also allow room for possible expansion (50% expansion area is required in New York State).

What is Gray Water?

Gray water is usually water from a laundry system, perhaps the effluent from a sump pump, the foundation footing drains, roof runoff, and sometimes shower drains. This water usually does not contain human waste products and does not need to be digested like human waste. The disposal requirements for this type of water are less stringent than those for human waste. If there is a space problem on your site, it may be possible to segregate the gray waste from the human waste and minimize the size of the system needed for control of the human waste. Your design professional (Licensed Engineer or Registered Architect) can advise you of your options in this area.

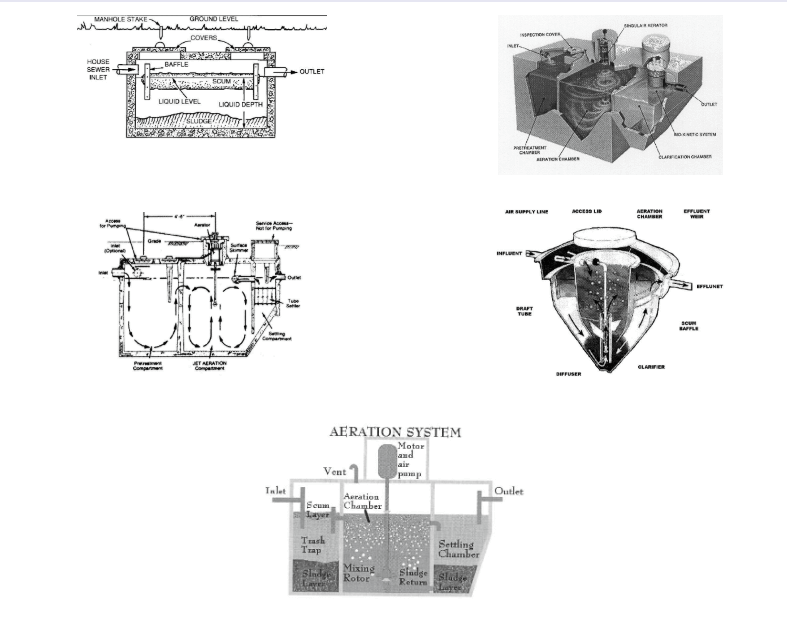

Alternative (Other Types of) Systems

The system discussed above is a conventional system installed in the soil that exists on the site. Where the site conditions do not lend themselves to installing this type of system, there are alternatives.

For example, if ground water or percolation rates are unsuitable, it may be possible to install what is called a “mound” system. In a mound system, a suitable soil is placed above the unsuitable soil. A conventional system is then installed in the mound. There are some additional requirements for this type of design.

If there is not enough room for a conventional leach field, it may be possible to install one or more cesspools, or seepage pits. These units are usually round, require less open ground, and are deeper than a conventional leach field. Again, there are specific requirements for these systems.

Conventional, mound, and seepage pit systems all work by what is called anerobic bacterial action. This means the bacteria work without oxygen. Some systems are designed to be aerobic – meaning the bacteria need oxygen (air); There are also hybrid systems that use a combination of anerobic and aerobic sections. Your design professional will advise you if one of the non-conventional systems is best for your needs.